Product Description:

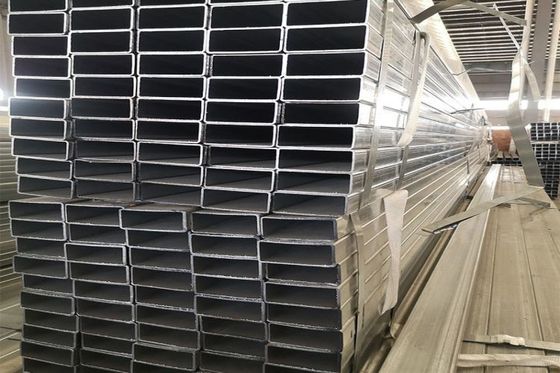

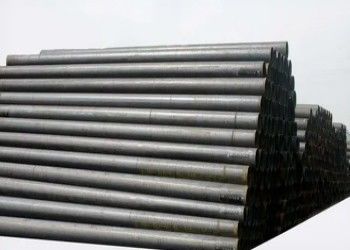

The LSAW Steel Pipe is a high-quality, reliable product designed to meet the demanding requirements of various industrial applications. With an outside diameter ranging from 355.6mm to 2320mm, this pipe is versatile and suitable for a wide array of projects, including oil and gas transportation, structural uses, and water supply systems. Among its diverse size options, the 24 inch steel pipe stands out as a popular choice due to its optimal balance of strength and capacity, making it ideal for large-scale pipeline systems. Additionally, the product line includes smaller dimensions such as the 2 inch galvanized pipe, which is perfect for smaller applications requiring corrosion resistance and durability.

Manufactured according to internationally recognized standards such as API 5L, EN10219, EN10210, and ASTM A252, the LSAW Steel Pipe ensures compliance with stringent quality and safety requirements. These standards guarantee that the pipes maintain exceptional mechanical properties, dimensional accuracy, and surface finish, which are critical for long-term performance in challenging environments. The steel grades available for this product include API 5L grades GR B, X42, X46, X56, X60, X65, and X70, as well as ASTM A53 grades GR A, GR B, and GR C. This wide range of steel grades allows customers to select the most appropriate material based on the intended application, pressure ratings, and environmental conditions.

To ensure the highest level of quality and reliability, the LSAW Steel Pipe undergoes comprehensive inspection and testing procedures. These include hydraulic testing to verify the pipe’s pressure resistance, eddy current testing for detecting surface and near-surface flaws, radiographic testing (RT) for internal defect identification, and ultrasonic testing (UT) for assessing wall thickness and integrity. Furthermore, the product can be inspected by third-party organizations to provide additional assurance and meet specific project requirements. This rigorous inspection process guarantees that every pipe delivered meets or exceeds industry standards, ensuring safety and performance in critical infrastructure projects.

When it comes to packaging and transportation, the LSAW Steel Pipe is carefully prepared to prevent damage during handling and shipping. The pipes are coated with black paint to protect against corrosion and environmental exposure. Additionally, beveling is applied to the pipe ends to facilitate welding and installation on site. End caps are also supplied to safeguard the pipe interiors from contamination and mechanical damage. This comprehensive transport package ensures that the pipes arrive at the destination in perfect condition, ready for immediate use.

The versatility of the LSAW Steel Pipe is further demonstrated by its suitability across various industries. The 24 inch steel pipe, for example, is widely used in pipeline construction for oil, gas, and water transportation, offering excellent strength and durability. Meanwhile, the smaller 2 inch galvanized pipe is commonly employed in plumbing, irrigation, and structural applications where corrosion resistance is paramount. This broad product range allows customers to find the perfect pipe size and specification to meet their unique project needs.

In summary, the LSAW Steel Pipe offers an exceptional combination of size flexibility, material quality, rigorous inspection, and protective packaging. Its compliance with major international standards such as API 5L and ASTM A53, along with the availability of multiple steel grades, makes it a reliable choice for engineers and construction professionals worldwide. Whether you require a robust 24 inch steel pipe for large-scale pipeline projects or a durable 2 inch galvanized pipe for smaller applications, this product delivers outstanding performance and value.

Technical Parameters:

|

Transport Package

|

Black Paint, Bevel Send, End Caps

|

|

Wall Thickness

|

5mm-50mm

|

|

Outside Diameter

|

355.6mm-2320mm

|

|

Standard

|

API 5L, EN10219, EN10210, ASTM A252 Etc

|

|

Usage

|

Structure Pipe, Pipe Piling Construction

|

|

Surface Treatment

|

Bare, Varnish Coating/Anti Rust Oil, FBE, 3PE, 3PP, Galvanized, Coal Tar Epoxy, Concrete Coating

|

|

Welded Line Type

|

Longitudinal

|

|

Inspection

|

With Hydraulic Testing, Eddy Current, RT, UT Or Inspection By 3rd Party

|

|

Steel Grade

|

API 5L: GR B, X42, X46, X56, X60, X65, X70; ASTM A53: GR A, GR B, GR C

|

Applications:

The JOHO LSAW Steel Pipe, manufactured in China and certified by ISO 9001, is a versatile and reliable product designed for a wide range of application occasions and scenarios. With an outside diameter ranging from 355.6mm to 2320mm and welded with a longitudinal seam, this steel round tube meets stringent industry standards such as API 5L, EN10219, EN10210, and ASTM A252, ensuring exceptional quality and performance.

In the construction industry, the JOHO LSAW Steel Pipe is widely used for structural frameworks, bridges, and infrastructure projects. Its high strength and durability make it ideal for supporting heavy loads and withstanding harsh environmental conditions. Additionally, the product’s availability with various inspection methods, including hydraulic testing, eddy current, radiographic testing (RT), ultrasonic testing (UT), and third-party inspection, guarantees superior safety and reliability for critical applications.

The product also plays a significant role in the oil and gas sector, where it is used for pipelines transporting oil, gas, and other fluids. The longitudinal welded line type ensures minimal leakage and robust resistance to pressure, making it suitable for long-distance transmission. Customers can order the steel pipes in various diameters and specifications, including 2 inch galvanized pipe and galvanized metal pipe options, which provide corrosion resistance and enhance longevity in outdoor and underground environments.

Industrial facilities rely on JOHO’s galvanized metal pipe and steel round tube products for manufacturing, machinery, and fluid transport systems. The pipes’ adaptability to various packaging requirements, such as black paint coating, bevel ends, and protective end caps, allows for customized solutions tailored to specific project needs. With a minimum order quantity of just 1 TON and competitive pricing ranging from USD 650 to USD 1500, JOHO offers cost-effective and efficient procurement options.

Logistics and delivery are streamlined with a commitment to dispatch products within 30 days, supported by flexible payment terms including LC and TT. This responsiveness ensures that clients across multiple sectors—from construction and oil & gas to industrial manufacturing—can rely on JOHO LSAW Steel Pipes for timely project execution. Overall, the JOHO brand stands out as a trusted supplier of high-quality steel round tube products, capable of meeting diverse application occasions and demanding scenarios worldwide.

Packing and Shipping:

Product Packaging and Shipping for LSAW Steel Pipe

The LSAW (Longitudinal Submerged Arc Welded) steel pipes are carefully packaged to ensure safe transportation and delivery. Typically, the pipes are bundled together with steel straps and fitted with wooden or metal end caps to protect the pipe ends from damage during handling and shipping.

For added protection, the bundles are often wrapped with waterproof materials such as plastic film or tarpaulin to prevent corrosion and contamination from moisture and external elements. Each bundle is clearly labeled with product specifications, batch numbers, and handling instructions to facilitate easy identification and inventory management.

During shipping, LSAW steel pipes are securely loaded onto flatbed trucks, railcars, or containers, depending on the destination and transportation method. Proper securing methods, including chocking and lashing, are employed to prevent movement and impact during transit.

Special care is taken for overseas shipments, where pipes may be packed inside containers with additional cushioning materials to withstand long-distance sea transport. Our logistics team coordinates with carriers to ensure timely delivery and compliance with international shipping regulations.

Overall, the packaging and shipping process for LSAW steel pipes is designed to maintain product integrity and quality from the factory to the end customer.

FAQ:

Q1: What is the brand name of the LSAW Steel Pipe?

A1: The brand name of the LSAW Steel Pipe is JOHO.

Q2: Where is the LSAW Steel Pipe manufactured?

A2: The LSAW Steel Pipe is manufactured in China.

Q3: What certifications does the LSAW Steel Pipe have?

A3: The LSAW Steel Pipe is certified with ISO 9001.

Q4: What is the minimum order quantity for the LSAW Steel Pipe?

A4: The minimum order quantity for the LSAW Steel Pipe is 1 ton.

Q5: What is the price range for the LSAW Steel Pipe?

A5: The price range for the LSAW Steel Pipe is between USD 650 and USD 1500 per ton.

Q6: How is the LSAW Steel Pipe packaged?

A6: The packaging of the LSAW Steel Pipe is done as per customer request.

Q7: What is the typical delivery time for the LSAW Steel Pipe?

A7: The delivery time for the LSAW Steel Pipe is within 30 days.

Q8: What payment terms are accepted for purchasing the LSAW Steel Pipe?

A8: Accepted payment terms include LC (Letter of Credit), TT (Telegraphic Transfer), etc.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!